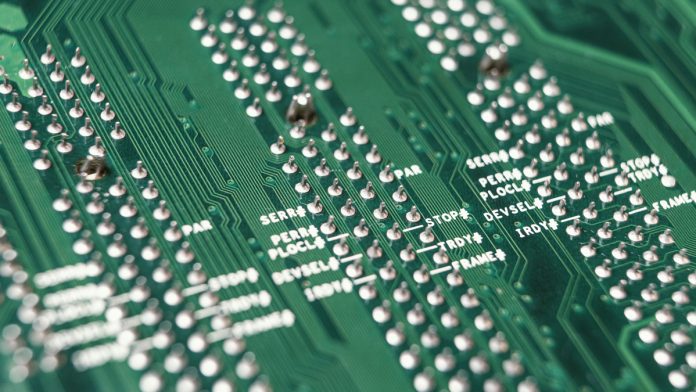

The cinema industry is embracing a transformative era where miniaturized engineering redefines projection and display capabilities. Breakthroughs across diverse fields, from nanomaterials and nano-fabrication to quantum effects and sustainable manufacturing, are converging to elevate visual storytelling. With innovations in circuit performance and energy efficiency, Nanotechnology in Resistor Design is now driving superior image fidelity and operational reliability. This article explores how these advancements are revolutionizing cinema systems, paving the way for vibrant, energy‑efficient theaters and next‑generation cinematic experiences.

| Table of Contents | |

|---|---|

| I. | Nanomaterials and Their Electronic Properties |

| II. | Nano-Fabrication Techniques |

| III. | Quantum Effects in Nanoscale Resistors |

| IV. | Integration into Cinema Projection and Display Technologies |

| V. | Thermal Management and Heat Dissipation |

| VI. | Flexible and Transparent Nanoelectronics |

| VII. | Smart Sensor Integration and the Internet of Things (IoT) in Cinema Systems |

| VIII. | Reliability, Longevity, and Robustness of Nano-Resistors |

| IX. | Interfacing Nanoelectronics with Conventional Circuits |

| X. | Sustainable Manufacturing and Environmental Impact |

Nanomaterials and Their Electronic Properties

Nanomaterials exhibit unique electronic characteristics that differ significantly from their bulk counterparts, delivering tailored conductivity and resilience. Their atomic-scale structures enable improved performance parameters critical for high-definition cinema systems. By applying Nanotechnology in Resistor Design, researchers fine-tune resistance and energy flow to boost image clarity and operational efficiency. These materials set the stage for innovations in display brightness and consistency, forming the backbone of advanced cinematic projection and next-generation electronic components.

Nano-Fabrication Techniques

Advanced nano‑fabrication techniques allow precise construction of electronic components using methods such as electron beam lithography and molecular self‑assembly. These processes craft intricate resistor networks essential for modern cinema displays and projectors. Incorporating Nanotechnology in Resistor Design, engineers achieve exceptional accuracy and minimal production variability, ultimately leading to higher resolution and more energy‑efficient visual systems. This precision manufacturing fosters breakthroughs in miniaturization, ensuring cinema technology remains at the forefront of visual innovation.

Quantum Effects in Nanoscale Resistors

At nanoscale dimensions, quantum effects such as electron tunneling and quantized conductance play a pivotal role in determining electrical behavior. Harnessing these phenomena within Nanotechnology in Resistor Design enables cinema systems to optimize signal processing and energy distribution. The result is a dramatic reduction in power loss and enhanced control over electronic responses, critical for high‑resolution projection systems. Such quantum‑driven enhancements provide a foundation for more efficient, responsive circuitry in future cinema technologies.

Integration into Cinema Projection and Display Technologies

The integration of nanoscale resistors into projection and display systems is revolutionizing image clarity, contrast, and color modulation in cinemas. Cutting‑edge circuit designs incorporating Nanotechnology in Resistor Design improve energy efficiency and reliability, driving sharper and more immersive viewing experiences. This technology facilitates precise control over light intensity, leading to enhanced picture quality in large‑scale displays and energy‑saving projectors. Such integration underscores a new frontier in cinematic technology, merging advanced electronics with superior visual performance.

Thermal Management and Heat Dissipation

Managing thermal loads is crucial in high‑power cinema systems where electronic components operate under intense conditions. Innovative cooling solutions synchronized with Nanotechnology in Resistor Design help mitigate heat buildup and optimize energy flow. By utilizing advanced materials and micro‑scale heat sinks, engineers can efficiently dissipate thermal energy, prolonging component life and performance. This focus on thermal management is vital in ensuring that cinema projectors and displays continue to deliver consistent performance, even during prolonged use.

Flexible and Transparent Nanoelectronics

Emerging flexible and transparent nanoelectronics are transforming cinema technology by enabling dynamic, adaptable display surfaces and projector designs. These innovations combine lightweight materials and flexible substrates to support curved and wearable screens. When integrated with Nanotechnology in Resistor Design, these systems offer high adaptability without sacrificing performance. This melding of flexibility with nanoscale precision paves the way for creative cinema applications, enhancing audience engagement with novel, portable, and visually striking display solutions.

Smart Sensor Integration and the Internet of Things (IoT) in Cinema Systems

Smart sensor networks coupled with IoT connectivity are reshaping cinema infrastructure by enabling real‑time system monitoring and adaptive control. Integrating these smart sensors with Nanotechnology in Resistor Design enhances signal accuracy and data transmission across critical circuit pathways. This technological synergy allows for predictive maintenance, automated adjustments, and optimized energy management, ensuring that cinema environments respond dynamically to changing conditions. The result is a more interactive and reliable audience experience, backed by sophisticated monitoring systems.

Reliability, Longevity, and Robustness of Nano‑Resistors

For cinema systems operating under constant demand, reliability and durability of components are paramount. By deploying advanced materials and protective coatings through Nanotechnology in Resistor Design, nano‑resistors achieve enhanced robustness against thermal and operational stresses. This engineering advancement guarantees consistent circuit performance and prolonged device life even in challenging conditions. Such steadfast reliability is critical in delivering uninterrupted, high‑quality cinematic experiences and in fortifying the technological foundation for future cinema innovations.

Interfacing Nanoelectronics with Conventional Circuits

Bridging the gap between cutting‑edge nanoelectronics and established conventional circuits demands innovative hybrid solutions. Leveraging Nanotechnology in Resistor Design, engineers develop interfacing techniques that harmonize nanoscale components with traditional circuitry. This approach improves signal integrity and operational efficiency, enabling seamless integration across systems. As cinema technology evolves, these interfaces ensure that legacy systems can coexist and synergize with new nano‑innovations, supporting a gradual transition to more advanced, energy‑efficient, and high‑performing visual platforms.

Sustainable Manufacturing and Environmental Impact

Eco‑friendly manufacturing practices are critical in minimizing the environmental footprint of advanced cinema technologies. By embedding Nanotechnology in Resistor Design within sustainable production workflows, manufacturers significantly reduce waste and energy consumption. The adoption of green materials and innovative recycling techniques ensures that electronic components are produced with minimal ecological disruption. This sustainable approach not only strengthens economic viability but also promotes responsible innovation, ensuring that the cinema industry leads with environmentally considerate and cutting‑edge technologies.